Nigiri Sushi Machine

Compact Sushi Machine with Shari-tray Transfer Unit

Model: SSN-JLX+TRS-JLX

Compact Sushi Machine with Shari-tray Transfer Unit

Optimal for Advanced Preparation and High-Volume Production

Fully automated, this machine handles every step—from tossing and weighing to forming the sushi rice and lining up the pieces on a tray. It enhances speed and efficiency, making your work easier.

The machine produces up to 4,200 pieces per hour, creating delicious Nigiri rice balls with a perfect melt-in-your-mouth consistency. It employs a unique forming process that preserves the grains of sushi rice. The interlocking safety cover provides complete protection for the transfer unit, enhancing safety.

What you can make

Nigiri sushi

Gunkan Sushi

Features

High Speed Production

50 nigiri can be transferred on tray in approx. 45 seconds.

Selectable Tray & Alignment

Tray & Alignment (Straight or Angled) are available

Advance Preparation and Volume Production

Make it easier to store and handle nigiri. Up to 250 nigiri can be stored in a rice container (GRC-20) by using nigiri trays (GRT-20).

Testimonials

Elevating Fast Casual with Robotic Expertise

Makimaki Sushi

NYC, NY

Specifications

| MODEL | SSN-JLX-EH+TRS-JLX-ET |

|---|---|

| CAPACITY | Max. 4,200 pcs / hr (as transfer speed) |

| DIMENSIONS | 751 w × 495 d* × 670 h mm * When tray removing: 745 d mm * Including Hopper lid rack |

| INPUT | AC 110-120 V, 60 Hz |

| POWER RATING | SSN-JLX-EH+TRS-JLX-ET: 380 W |

| HOPPER CAPACITY | Standard hopper (SSN-JLX) : Approx. 5.5 kg Large hopper (SSN-JLX / SSN-JLX-EH) : Approx. 10 kg |

| WEIGHT PER PIECE | 12g to 22g * * 12g to 16g requires different mold unit |

| HARDNESS SETTING | Soft to Hard (7 steps adjustment) |

| OPTION | KHS Tray Wasabi unit (SSN-JLX) |

You may also like

-

Super Compact Sushi Machine

Model: S-CubeDetailRegular price $0.00Regular priceUnit price / per -

INARI Sushi Robot

Model: FIS-SNDDetailRegular price $0.00Regular priceUnit price / per -

Onigiri mold for Rice-Serving Machine

Model: TOADetailRegular price $0.00Regular priceUnit price / per -

Fuwarica Rice-Serving Machine

Model: GST-FBBDetailRegular price $0.00Regular priceUnit price / per -

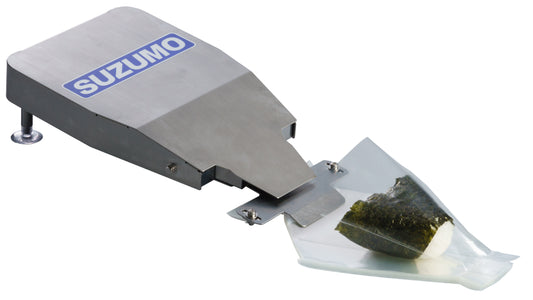

Onigiri Film Opener

Model: FHB-SHCDetailRegular price $0.00Regular priceUnit price / per -

Table Top Type Hand Pressing Forming Unit

Model: THS-DRADetailRegular price $0.00Regular priceUnit price / per -

OMUSUBI Making Machine

Model: MOS-FMCDetailRegular price $0.00Regular priceUnit price / per -

Compact Wrapped Sushi Machine

Model: SGP-SNBDetailRegular price $0.00Regular priceUnit price / per -

Sushi Chef SUKETTO

Model: SSG-SCSDetailRegular price $0.00Regular priceUnit price / per -

Compact Sushi Machine with Shari-tray Transfer Unit

Model: SSN-JLX+TRS-JLXDetailRegular price $0.00Regular priceUnit price / per -

Compact Sushi Machine

Model: SSN-JLXDetailRegular price $0.00Regular priceUnit price / per -

Automatic Sushi Roll Cutter

Model: SVC-ATCDetailRegular price $0.00Regular priceUnit price / per -

Rice Sheet Making Machine

Model: SVS-FCADetailRegular price $0.00Regular priceUnit price / per -

Roll Sushi Making Machine

Model: SVR-NXADetailRegular price $0.00Regular priceUnit price / per -

Roll Sushi Making Machine

Model: SVR-BXADetailRegular price $0.00Regular priceUnit price / per -

SHARIKKA Compact Cooked Rice Mixer

Model: MCR-SSCDetailRegular price $0.00Regular priceUnit price / per -

SHARIKKA Cooked Rice Mixer

Model: MCR-ASBDetailRegular price $0.00Regular priceUnit price / per -

Rice Cooker

Model: JIW-G541DetailRegular price $0.00Regular priceUnit price / per -

Kubota Rice-Washing Machine

Model: KP720NA-ULDetailRegular price $0.00Regular priceUnit price / per